Post-Process Superfinishing of Additively Manufactured Components for Next-Gen Space Application

By : Nathan Michaud ,

By : Nathan Michaud ,

Abstract: Growing adoption of Metal Additive Manufacturing (AM) technologies promises revolutionary beneficial changes in manufactuing, however, in many industries, particularly industries such as Aerospace (with complex qualifying standards), challenges in the form of various defects/flaws (both surface and sub-surface) inherent to the printing process serve as barriers to full adoption of Metal AM. These flaws can reduce performance and potentially lead to critical component failure, and no single existing post-process surface finishing technique exists which can holistically remediate the flaws without additional barriers to production/cycle-times and/or cost. This paper will serve as a primer to both the promises and the challenges inherent to Metal AM as well as research conducted by REM Surface Engineering to develop a novel optional finishing technique (OFT) capable of remediating all surface/subsurface defects with minimal impacts to production and cost.Furthermore, the paper will expire data on performance enhancements imparted by the OFT, current applications of the OFT, as well as potential future industry and competent applications.

REM Surface Engineering and Additive Manufacturing

The past decades have seen Additive Manufacturing (AM) develop from an idea to a groundbreaking technology, revolutionizing metal component manufacturing across many industries. In 2011, Elsevier published 4523 articles relating to AM.[[i]] In 2021 they published 19,592. On the business side, the global market revenue from 2014 to 2020 grew from $4.1 billion to $12.6 billion USD.[[ii]] What’s not to love about the promise of additive manufacturing: greatly reduced lead times, the ability to print complex designs and features not possible with traditional manufacturing methods, and the implementation of novel alloys and superalloys with extremely high mechanical, chemical, and thermal performance characteristics? The list of potential benefits grows across applications and industries year over year as print methods and parameters become more tested and refined. However, Metal AM is still hindered by various inherent challenges that have served as roadblocks to full implementation, particularly in highly qualified industries like the Aerospace and Space Industries.[[iii]]

Unfortunately, across nearly all metal AM print methods and parameters, as-printed components carry a bevy of flaws and issues which all have the potential to hinder safe handling, deter applicability, reduce performance, or even lead to critical component failure.[[iv]] These flaws include high surface roughness/texture, partially sintered/unsintered powders, and surface and near-surface porosity as artifacts of the printing process. Furthermore, with the ability to generate organic and complex designed AM components with features such as internal channels and lattice structures, these defects are often further complicated by lack of access and visibility. Moreover, many print methods still require the printing of support structures to complement component integrity, which adds post-process complexity for finished components.

REM Surface Engineering, founded in 1965, has been a leading provider of isotropic superfinishing (ISF®) services in traditional industries for decades. Our patented and proprietary chemical and mechanical/vibratory finishing technologies allow for precision-controlled surface finishing of metal components via a subtractive process (Figure 3.)

Working as a supplier for traditionally manufactured metal components for decades has put us in a uniquely qualified position as we see Metal AM begin to take hold; how could we adapt and evolve our proven, existing ISF® technologies to serve as a bridge for Metal AM technology to grow from concept to full implementation? Our expertise told us that existing methods of post-process surface finishing would not suffice for Metal AM components; given complex surface and near surface defects and line-of-sight limitations inherent to many AM components, no existing technology existed which represented a single, holistic solution able to address all component issues and barriers faced by Metal AM.

The Research

Three years ago we set out to find a solution. Building on existing self-funded research, we partnered with NASA on our first SBIR in 2018. Our goal seemed simple, but represented a huge challenge: test and validate known isotropic superfinishing technologies in both single and combinatory use to identify an optimal finishing technique (OFT) capable of remediating all surface and near surface defects via controlled surface material removal, while at the same time imparting mechanical performance improvements over the as-printed components.[[v]] The process also needed to be safe, repeatable, applicable to various/all Metal AM print methods, require minimal operator interaction, not require excessive cost/overhead, and have a cycle time that did not negatively impact production timelines. With the preexisting knowledge that solely mechanical and abrasive technologies would neither address sub-surface defects nor areas limited by lack of line-of-sight access, we focused on methods including Electropolishing (EP), Chemical Polishing (CP), and Chemical + Mechanical Processing (CMP). Adapting formulations and process parameters focused on NASA’s then priority nickel-based superalloy, Inconel 625, each method was applied singularly and in combination with other methods, and specimens were tested for comparison over their as-printed conditions. Surface condition improvement was assessed via contact profilometry and optical microscopy, sub surface condition was tested via X-Ray CT Scan and SEM of cross-sectional cuts, and mechanical performance was tested via tensile strength testing, as well as high-cycle and low-cycle fatigue testing.

The Results

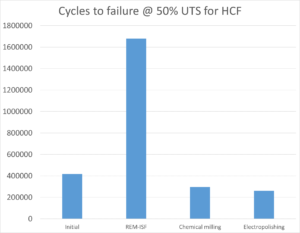

Our results were definitive and clear: EP was eliminated as a viable solution due not only to its high cost and overhead requirements, but also due to the difficult-to-control removal rate leading to excessive rounding of component edges. CP, once formulations had been optimized, showed high success to planarize and address all surface defects, ability to access non-line-of-sight surfaces and internal channels, with a high (but controllable) material removal rate. CMP showed the best results for addressing surface and near surface defects, with a controllable material removal rate, as well as imparting the most significant improvements to mechanical performance as seen in the fatigue data (Figure 1). As such, a combination of CP + CMP was identified as the OFT, capable of addressing all surface/near-surface defects with minimal overhead in a highly-controllable and repeatable process.

Figure 1: High cycle fatigue cycles to failure (R = 0.1, RT, and 60 Hz) at 50% UTS for L-PBF IN-625 as-printed and surface finished by different technologies, showing success of REM ISF® process in improving fatigue life.

Our 100% deliverable success in that initial SBIR with NASA has grown manifold; research with NASA now includes an equally successful Phase II to expand formulation capabilities to include IN-718, JBK-75, and NASA HR-1, with a priority to scale processing to accommodate sub-scale propulsion components for Artemis missions[[vi]], Phase III funding to process nozzles and firing chambers for hotfire testing[[vii]] (Figure 2) as well as advancing research on finishing for internal cooling channels[[viii]], and now Phase II-E funding to adapt capabilities and equipment to process full-scale propulsion components in the next year.

Figure 2: Additively manufactured (Laser Direct Energy Deposition) firing chamber and rocket nozzle processed by REM Optimized Finishing Technique survives 23+ hotfire tests (Source=NASA)

Additionally, our research with NASA has led to complementary Phase 1 SBIR research for the US Air Force to adapt our OFT for additively manufactured aluminum components (AL-6061RAM-2)[[ix]], as well as a Phase II to adapt our OFT to accommodate F357, Ti-6Al-4V, and Scamalloy[[x]], as well as a leveraging our post-process surface finishing expertise to adapt AM print parameters and facilitate AM adoption across Air Force depots for Rapid Sustainment and Fleet Readiness[[xi]]. Since 2018, REM has received over $3.1 Million in government research funding for post-process surface finishing technologies for Metal AM. The OFT itself and contingent adaptations have been fully commercialized for all industries including Aerospace and Space partners (specific customer names are confidential) with revenue totaling over $1,500,000, with an average growth of 200-300% per year for the last 3 years.

The Potential

The game-changing nature of Metal AM and REM’s post-process superfinishing technology go hand in hand, and data supporting the complementary benefits of implementing our technology continues to grow. New research data continues to validate improvements to fatigue life and tensile strength, and have begun to explore hypotheses around improved corrosion resistance and thermal resistances/strength. Examples of existing and potential space component implementation include: nozzles; combustion chambers; barrels; thruster chamber assemblies; cooling channels; fuel injectors; impellers & blisks; structural components including brackets, lattices, and honeycombs; and power transmission components. Proven benefits to date include: increased high cycle fatigue life; uniform hotwall thickness reduction for cooling; uniform surface roughness reduction for cleanliness/coating and overlap adhesion; cooling channel FOD removal; cooling channel/fuel injector roughness reduction for reduced flow resistance/pressure; controllable cooling channel/fuel injector diameter increase; removal of detrimental oxide layers due to HIP; elimination of granular roughness; improved contact fatigue life for power transfer components; improved flow dynamics for turbomachinery; uniform metal removal from highly complex component shapes including iterative/bionic designs, lattices, and honeycombs (allowing for ultra-thin wall generation.) Each of these benefits and component applications can translate to any and all industries and any and all AM print methods with similar needs and applications, including military, medical, automotive, power generation, bearings, firearms, gearing, metal injection modling, motorsport, decorative, etc.

The Future

As we continue to develop and adapt solutions to meet the needs of our customers and research partners, our catalog of supporting data continues to reveal more and more exciting potential applications for Metal AM in conjunction with our post-process superfinishing technology. The next stages of research continue to grow (literally) to include not only full-scale rocket propulsion component processing capabilities, but also optimizing our technology for installation at customer locations to facilitate fully realized in-situ AM printing capabilities anywhere on Earth, and someday the Moon and Mars.

Figure 3: Visualization of proprietary REM ISF® Chemical and Mechanical Polishing process, a subtractive superfinishing process capable of removing microscopic amounts of surface material via the repeating cycle of creating/removing a self-assembled monolayer (SAM).

References

[i] Science Direct Search Results. (2021, August 17). Science Direct. https://www.sciencedirect.com/search?qs=additive%20manufacturing&lastSelectedFacet=years

[ii] Hubs: A Protolabs Company. (2021). Additive Manufacturing Trend Report 2021. https://f.hubspotusercontent10.net/hubfs/4075618/Additive%20manufacturing%20trend%20report%202021.pdf?utm_campaign=Gated%20Content%20Downloads&utm_medium=email&_hsmi=82605589&_hsenc=p2ANqtz-8pVVH1TWB5lhXxlFFDFsuKkXC6nj7FtiZbBWqhdmdevavYK8SBIfKoMk5cy3L1VLE25pqHgBaoVd9k7TwJqX0iPykw67vd2Rk4WFcJMZRbkntIF6U&utm_content=82605589&utm_source=hs_automation

[iii] Diaz A (2019) Surface texture characterization and optimization of metal additive manufacturing-produced components for aerospace applications. Additive Manufacturing for the Aerospace Industry, 341–374. https://doi.org/10.1016/b978-0-12-814062-8.00018-2

[iv] Townsend A, Senin N, Blunt L, Leach RK, Taylor JS (2016) Surface texture metrology for metal additive manufacturing: a review. Precision Engineering, 46:34–47. https://doi.org/10.1016/j.precisioneng.2016.06.001

[v] Diaz, A (Principal Investigator) (2018) NASA Phase I – 80NSSC18P2192 – Internal/External Surface Finishing of Additively Manufactured IN-625 Components

[vi] Diaz, A (Principal Investigator) (2019) NASA Phase II / II-E – 80NSSC19C0211 – Surface Finish & Post-Process Optimization of Ni-Based Superalloy AM Components

[vii] Porter, Molly. “3D Printed Rocket Engine Parts Survive 23 Hot-Fire Tests.” NASA Press Release [Huntsville, Alabama], 8 Dec. 2020, www.nasa.gov/centers/marshall/news/releases/2020/3d-printed-rocket-engine-parts-survive-23-hot-fire-tests.html.

[viii] Diaz, A (Principal Investigator) (2020) NASA Phase III – 80NSSC20C0080 – Surface Enhancement using ISF® of Additively Manufactured Hardware

[ix] Flores Delgado, J. (Principal Investigator) (2020) AF Phase I – FA864920P0930 – Internal/External Surface Finishing of Additively Manufactured Aluminum-6061-RAM2 Components

[x] Diaz, A (Principal Investigator) (2021) AF Phase II -FA864921P0815 – Internal/External Surface Finishing of Additively Manufactured Aluminum-Based Components

[xi] Diaz, A (Principal Investigator) (2021) AF D2P2 – FA864921P0854 – Development of Manufacturing, Heat Treatment, and Surface Finishing Guidelines to Yield Ready-to-Use IN- 718 Additive Manufacturing Components

Please fill out the information below to receive the selected resource.

Please fill out the information below to receive the selected resource.