FOR IMMEDIATE RELEASE

Brenham, Texas, [March 9, 2019]– REM Surface Engineering completes Phase I funding through the National Aeronautics and Space Administration’s (NASA) Small Business Innovation Research (SBIR) program. REM Surface Engineering’s proposal, “Internal/External Surface Finishing of Additively Manufactured IN-625 Components”, was awarded in June 2018 with submission of final reports and deliverables scheduled for February 15, 2019. REM successfully completed 100% of all objectives. These deliverables include:

- Reducing the surface roughness to a 32 μ” RMS surface finish or lower;

- Removing 0.02 – 0.05” of material uniformly from the internal and/or external surface of geometrically complex Inconel 625 AM components in a 24-hour cycle;

- Eliminating surface defects that would otherwise result in reduced tensile and/or fatigue properties;

- Capable of surface finishing 100’s or 1000’s of components without excessive footprint requirement;

- Can potentially be automated, is scalable, and needs minimal operator interaction;

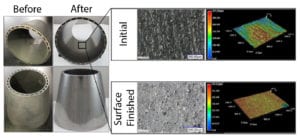

Figure 1: Example of the capability of the technology developed as part of the Phase I Program. The left side shows the as-built DMLS IN-625 subsize fuel nozzle before and after the surface finishing by REM. The right shows the progression of the surface texture through the surface finishing process.

REM has generated a new technology capable of uniformly processing IN-625 AM components and imparting improved fatigue/mechanical performance with greatly enhanced surface conditions. Many REM Surface Engineering employees contributed to the project’s success including Dr. Agustin Diaz, Patrick McFadden, Nathan Michaud, Will Wirtz, Lane Winkelmann.

About REM Surface Engineering

REM Surface Engineering, the inventor of the ISF® Process, the Rapid ISF® Process, the Extreme ISF® Process, and the REM® Process, is a global leader in providing surface engineering solutions. The REM’s isotropic superfinishing technologies are value-adding and performance-enhancing improvements to conventional machining operations such as grinding and lapping. Founded in 1965 in Southington, CT by Robert Michaud, REM Surface Engineering is a family-owned company that has proudly been serving our partners and customers for over 50 years. REM Surface Engineering operates four locations in Brenham, TX, Southington, CT, Merrillville, IN, and St. Neots, UK that provide products and services globally. For more information, please visit www.remchem.com.

Media Contact: Christina Michaud

cmichaud@remchem.com